JIOUEE METALS - a division of SPSS Metals

Material | titanium,Gr1,Gr2 |

Outside diameter | 9.52 mm-50.00 mm |

Wall thickness | 0.53 – 2.0 mm |

Length | 15 m or more or less |

Temperature range | - 50°C -200°C |

Working pressure | 3.5 Mpa |

Use | Water tank, boiler, heat exchanger unit, absorption type refrigerator, turbo refrigerator and screw refrigerators; distillation facility with multiple effects etc. |

Titanium Twisted Tube is a new technology in China. Now we can make the diameter is Φ12.7mm to Φ50mm, thickness is 0.6mm, 0.8mm or1.0mm

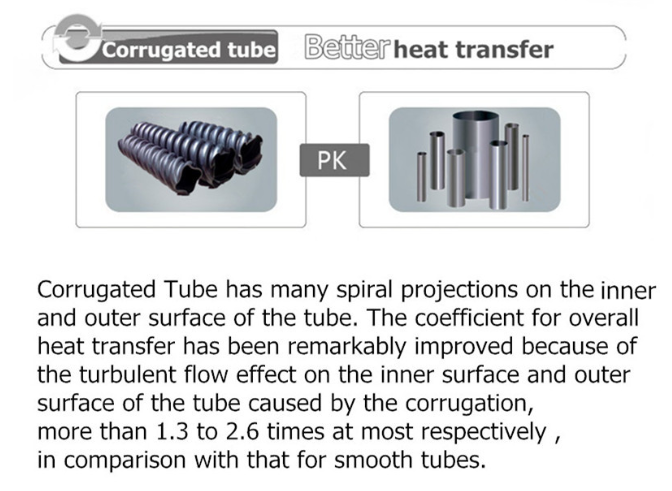

Compare to the normal titanium heat exchanger, titanium twisted tube one can be their 1.3-2.6times

Comparing between normal titanium heat exchanger and titanium twisted tube heat exchanger:

Titanium straight tube | Titanium Twisted Tube | |

heat exchange area | 1:1 | The proportion of titanium straight tube and titanium threaded pipe is 1.3:1. After rolling into 1 meter titanium threaded tubing,it need 1.3 meter titanium straight tube (The ratio has a direct relationship with the depth and the quantity of thread) |

Water flow rate | Small resistance and fast speed | Its heat transfer time is long, because the big resistance and slow velocity when the medium through the internal thread channel. |

Turbulent reactive | Molecular activity in general when kick through the smooth surface, | the molecules activity will be increased which turbulent in the wake of screw channel. |

Cleanse scale | ordinary | Turbulence form rotating flushing, which increased cleaning scales ability |

The structure, size, welding head | standard | It can swaps without preconditions with titanium straight tube, but it needs smaller volume, because of the high efficiency. |

The total thermal efficiency | standard | It is 1.3—2.6 times for titanium straight tube. (The factors has a direct relationship with the depth and the quantity of thread) |

Titanium Twisted Tube Features:

1.High efficiency, coefficient up to 10000 W/m^2*deg.C, Heat transfer capacity 1.3-2.6 times traditional tubes.

2.Compact configure, occupy small area ,one tenth as the traditional equipments.

3.Titanium material, endure high temperature, pressure and corruption.

4.Design flux speed is 5.5m/s, less dirt.

5.ASME standard

6.Easy clean and maintain

7.Big flow volume

8.Compactable

9.Fully welded construction.

10.Easy installation and durable.

Titanium Twisted Tube Application:

1.Food industry: Juices, beverages, sauces, dairy,deserts, fruit puree, whole fruit, catering, convenient food, pasteurization.

2.Industry: Chemical, petrochemical, polymers,heating, cooling, condensation, crystallization,evaporation, energy recovery.

3.Environmental: Waste water, environmental waste concentration, evaporation, sludge, pasteurization.

4.Bio-energy: Bioethanol, biodiesel, biogas, cogeneration.

Send us email for technical support [email protected]